Newsletters

- Sobono and V8 Environmental signed a joint venture agreement to develop the Rexus Bio-resource Valorisation Centre in Singapore

- Sort your food waste with OTTER

- A Sustainability Adventure at Gardens by the Bay – Dec 2023

- Feeding our Future: Building an Agri-Food Hub for All

- Sobono Group - Playing our part in Singapore's "30 by 30" Food Story through Renewable Energy, Circularity and Sustainability Strategy

- SOBONO’s insight featured in UOB Newsletters

- SLNG - Sobono Group Awarded JIIC 2021 with RUV Concept

- Looking Ahead - Jan 2022

- Agriculture Operations - ANI & Booking Module Development - Mar 2021

- Awarded ECPM project for 12.5 MWE FiT-Certification of Biogas Co-Generation Plant Expansion - Feb 2021

- Introducing High Performance Heavy Machinery to Largescale Agriculture - Jun 2019

- Sobono Greenland Commissions its First Fleet of Farm Tractors and Implements - Jan 2019

- Corn Cultivation in South Mindanao - Corn Pickers in Action (Nov 2018)

- Asian Power & Energy Innovation Award at PowerGen Asia 2019 - Sep 2019

- Introduction of Napier as Energy Crops - Biogas Cogeneration Plant Expansion - Sep 2019

- Incorporation of Sobono Greenland Pte. Ltd. - Oct 2018

- Biogas Power Plant with WWTP EPC - Oct 2017

- Operation & Maintenance Contract - May 2017

- Biomass ORC Plant EPC - May 2017

- Microturbine C65 - May 2014

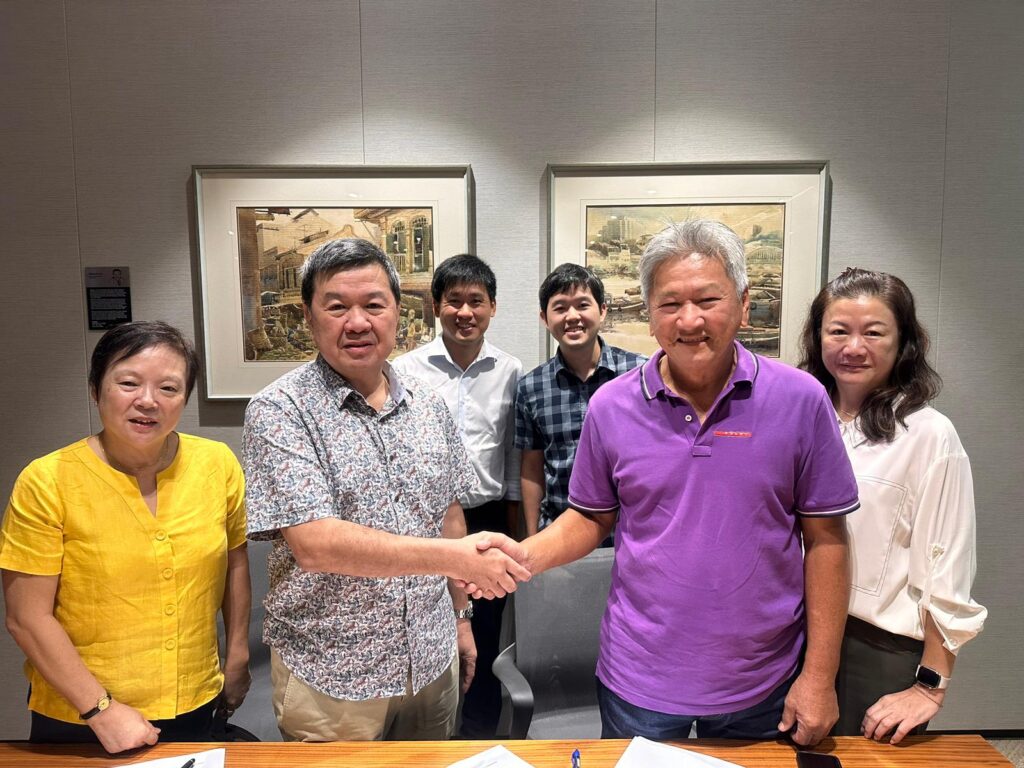

Sobono and V8 Environmental signed a joint venture agreement to develop the Rexus Bio-resource Valorisation Centre in Singapore.

Mr Oh Wee Khoon (centre-left), Managing Director of Sobono and Mr Er Kee Sing (centre-right), Managing Director of V8 confirmed the partnership with a handshake in the Joint Venture signing ceremony.

Sobono Pte Ltd (“Sobono”), a proponent of clean & energy solutions, and V8 Environmental Pte Ltd (“V8”), a pioneer waste management company, have announced a momentous strategic joint venture to incorporate and invest in RExus Bioenergy Pte Ltd to spearhead the development of an innovative and circular Bio-resource Valorisation Centre (“BVC”) in Singapore. The BVC highlights a renewable energy-certified power-certified Waste Wood-to-Energy (“WWtE”) Plant. The Joint Venture Agreement was signed on the 29th November 2023.

The two companies were brought together through the introduction by Enterprise Singapore in 2019. Sharing a common vision for a more sustainable Singapore, this collaborative effort represents a significant advancement in promoting waste-to-clean energy initiatives in response to the Singapore Green Plan 2030. Sobono Group and V8 Environmental are committed to bringing their expertise and resources to ensure the success and sustainability of this green project.

This facility leverages two key attributes of the joint venture partners: Sobono Group’s circular concepts and Sobono Energy’s expertise in the design, construction & operations of waste-to-energy plants, and V8 Environmental’s market knowledge and strength in the Singapore waste wood industry, providing Rexus Bioenergy feedstock sustainability and resilience.

This joint venture reflects a shared vision between the two companies, aimed at converting valuable but finite waste resources in Singapore to green energy through the most efficient means of power generation to make a significant difference in Singapore’s renewable energy landscape.

Oh Wee Khoon, Founder and Managing Director of Sobono Group, expressed his enthusiasm about the collaboration, stating, “This joint venture serves as a concrete manifestation of our shared commitment to propelling the development of sustainable energy solutions, fully aligned with the Green Plan 2030. Through this collaboration with V8, we intend to showcase the feasibility of harnessing renewable energy from waste biomass, broadening Singapore’s energy portfolio beyond just solar power.”

Derrick Yu, Chief Operating Officer of V8 Environmental, expressed, “V8 takes great pride in participating in this collaborative endeavour. Our proficiency in environmental sustainability aligns well with Sobono’s objectives. Together, we are well-positioned to overhaul and establish new benchmarks in the waste biomass industry, which we believe could contribute more towards a more sustainable future in Singapore.”

The RExus Bioenergy BVC is in preliminary development with land accusation as one of its key milestones, and the Board revealed that the commencement of operations is expected to be in Q1 2026.

For media inquiries, please contact:

|

Sobono Pte Ltd:

Zhang Fangmin Public Relations Email: fangmin.zhang@sobono.coms.sg Phone: +65 8657 7612 |

V8 Environmental Pte Ltd:

Eileen Yeo Business Development Email: eileen@v8.com.sg Phone: +65 9693 4015 |

About Sobono Group:

Sobono Group is an organisation that provides an array of renewable energy options and helps them support reducing carbon footprints within the organisation by providing scalable, comprehensive and clean energy products and solutions, bringing a positive impact on the environment, such as climate change from energy and fuel consumption, water and soil depletion, and acidification. Concurrently, we invest in a long-term growth objective with an increased emphasis on the Southeast Asia region.

About V8 Environmental:

V8 Environmental has been involved in the waste management industry for over two decades, supporting local authorities and industrial partners in sustainable waste management. V8 draws on the expertise they have been developing to help our partners manage their solid and liquid waste efficiently.

Sort your food waste with OTTER – A Smart, Interactive and Hygienic Food Waste Collection Bin

Sobono unveiled its revolutionary OTTER (Organic Transit Towards Energy Recovery) unit during the soft launch held on 12 January 2024 in Vidacity.

This cleverly designed food waste collection bin aims to tackle Singapore’s food waste challenge head-on, encouraging residents to embrace food with the ease of waste sorting design.

Addressing a Critical Need:

Food waste currently dominates Singapore’s waste streams, but only 18% is recycled. Improper segregation hinders efficient downstream processing, posing a significant challenge.

Inspired by the kampung spirit,, where household food waste was collected as animal feed, OTTER revives this practice of collecting food waste for upcycling, this time with a modern twist:

- Automated with SMART Controls

User-oriented and adaptable to Singapore’s hot and humid climate, OTTER tackles the technical limitations of traditional food waste collection. Odour control is paramount: upon approach, the lid automatically opens, activating an air pump to keep any unpleasant smells in the bin. After depositing the waste, a weight display motivates responsible disposal. Regular disinfectant dispersal further ensures hygiene and a slower rate of decomposition.

- Interactive and Informative:

The intuitive display empowers users to visualise the positive impacts of their actions. Understanding our food ecosystem is crucial for Singapore’s journey towards food security. For operators, OTTER provides real-time cloud monitoring and convenient alert messages for streamlined maintenance and waste collection.

Habit-Forming, Future-Focused:

By encouraging responsible habits and mindful food waste management, OTTER paves the way for a transformed landscape. Sobono partners with downstream food processors to convert collected waste into valuable products like biogas and compost.

“Sort Your Food Waste, Make It Your Habit.” Step into a brighter tomorrow with Sobono’s initiative, where food waste becomes a stepping stone towards a more sustainable, connected future.

For sales and general enquiry, please contact us at

E-mail: sales@sobono.com.sg

Tel: +65 6773 0219

A Sustainability Adventure at Gardens by the Bay – Dec 2023

To cap off the year with a meaningful and sustainable company event, the Sobono team and our families ventured into the wonders of Gardens by the Bay. The day unfolded amidst awe-inspiring nature, cutting-edge sustainable innovations, and, of course, delectable bites.

Under the insightful guidance of Mr Rodericks Wong from the Gardens’ Sustainability Team, we explored hidden corners, unveiling the design philosophies and unwavering commitment to environmental stewardship that defines Gardens by the Bay.

We peered into the hidden-from-sight Biomass Power Plant and its waste-to-energy fueled by recycled wood and horticulture waste. The resilience of nature captivated us as we learned how mangroves dance between fresh and salt waters at Kingfisher’s Park, a constant reminder of Singapore’s wondrous biodiversity. From breathtaking panoramas atop the Supertree Observatory to tranquil meanderings through the Flower Dome and Cloud Forest, every moment thrummed with the serene beauty of nature.

Stepping into the Flower Dome and Cloud Forest, powered by the biomass energy plant, we marvelled at a sustainable Eden. Laughter and joyful chatter filled the air as we savoured a delicious lunch with our fellow Sobono families, recharging our spirits and weaving closer bonds.

A special shout-out to our team member Wenyang for achieving the double triumph this year – welcoming a precious child and being promoted to 2nd Grade Engineer!

As we turn the page to 2024, let’s carry the memories of this day close, embracing green solutions, forging strong bonds, and making the year ahead one of vibrant growth and shared success.

The Singapore Food Agency (SFA) exhibition, “Feeding our Future: Building an Agri-Food Hub for All,” was launched by Deputy Prime Minister and Minister for Finance, Mr Lawrence Wong, on 02 September 2023. A key highlight of the exhibition is the vision for Lim Chu Kang (LCK) as Singapore’s flagship agri-food production hub of the future.

MKPL Architects Pte Ltd, together with Henning Larsen, Ramboll, Sobono, KuiperCompagnons, Priva, WSP and AECOM are extremely proud and honoured to be given the opportunity to work with SFA on this LCK master plan, envisioning its transformative blueprint to safeguard Singapore’s food future. The project is of national significance as it will be contributing to Singapore’s ‘30 by 30’ vision, which aims to build the agri-food industry’s capability and capacity to sustainably produce 30 per cent of Singapore’s nutritional needs by 2030.

Our multi-disciplinary team’s concept master plan addresses key challenges of Singapore’s limited land resources for agriculture and aquaculture with careful consideration for the ecological sensitivities of the site. The master plan proposes innovative farming typologies and technologies that would achieve the food production goals whilst incorporating the natural character of Lim Chu Kang. The concept includes holistic ecosystems to enable sustainable, productive agri-food production, a framework for circular resourcing and opportunities for businesses and agri-food workers.

Stacked Farming and Circular Thinking

The first of its kind, this ground-breaking approach is tailored to suit Singapore’s climate and the coastal topography of the site. The plan proposes a 3-layer stacked farm prototype that caters to different levels of food production and unique production conditions, e.g., indoor mushroom and beansprout farming in the basement where sunlight is not required, an enclosed environment with regulated indoor climate and temperature for leafy vegetables, greenhouses for fruit and vegetables that thrive in natural daylight, and indoor farms for fish and crustaceans with water and air treatment.

Circular thinking guides the district-wide design to boost energy efficiency and operational resilience, for example, turning agricultural waste into assets using anaerobic digesters.

Coastal Protection and Biodiversity Preservation

Coastal protection measures are significant drivers of the design. The building and green spaces are carefully integrated to create multi-functional spaces that maximise food production areas whilst addressing rising sea level concerns and the ecological sensitivity of the site.

The gradated-farm approach informs the zoning strategy. The core production zone is envisaged as an intensive farming area with stringent biosecurity controls. It is located farthest from the nature reserve. A transition production zone is introduced between the core production zone and nature areas, with indoor farms thoughtfully integrated into the surrounding context to minimise visual impact within the biodiversity areas.

Preserving the site’s characteristics is an important consideration, as Lim Chu Kang is surrounded by Sungei Buloh Wetland Reserve and Kranji Marshes. The landscape will respond to the ecosystems in the area and provide sensitive, low-impact recreational opportunities for the public.

Team Members

| Lead Consultant & Architect | MKPL Architects Pte Ltd |

| Urban Planner & Landscape Design | Henning Larsen |

| Transport Planner | Ramboll |

| Civil & Structural Engineering | Ramboll |

| Environment & Biodiversity | Ramboll |

| Flood Resilience & Coastal Protection | Ramboll |

| Waste Management, Circularity & Sustainable Energy | Sobono Pte Ltd |

| Mechanical & Electrical Engineering | WSP |

| Quantity Surveying | AECOM |

| Agri-Food Production | Kuipercompagnons B.V |

| Food Technology & Biosecurity | Priva B.V |

Illustration of the 3-layer stacked farm typology with integrated utility corridor connected to shared services hub

Credit: MKPL Architects Pte Ltd

Seamless integration of building and landscape to optimise landuse whilst addressing coastal protection needs and existing site ecology

Credit: MKPL Architects Pte Ltd

Retaining the rustic nature of Lim Chu Kang

Credit: MKPL Architects Pte Ltd

Key District Markers such as Gateway Centre promote greater community interest and awareness in local agriculture

Credit: MKPL Architects Pte Ltd

Photo Credit: : Sobono Group

MKPL Architects Pte Ltd, together with Ramboll, Sobono, KuiperCompagnons, Priva, WSP and AECOM, has been awarded a significant project by the Singapore Food Agency (SFA) to deliver the country’s first high-tech agri-food cluster master plan in Lim Chu Kang.

The team led by MKPL has been carefully assembled, with expertise in master planning, architecture, urban design, landscape design, ecology, water and wastewater, coastal protection, transport, renewable energy, circularity and sustainability, farm planning and technology, engineering and cost planning.

The team is extremely proud and honoured to be given the opportunity to work with SFA on this transformative project. The project is of national significance as it will be contributing to Singapore’s ‘30 by 30’ goal, which aims to build the agri-food industry’s capability and capacity to sustainably produce 30 per cent of Singapore’s nutritional needs by 2030.

SFA envisions Lim Chu Kang to be a high-tech, highly productive, and resource-efficient agri-food cluster. Spanning about 400ha of land, the master plan identifies new public infrastructure and shared facilities to uplift the agri-food sector, boosts food production, and creates good green jobs for Singaporeans. The master plan proposes innovative farming typologies and technologies which would achieve the food production goals whilst incorporating the natural character of Lim Chu Kang.

UOB Industry Perspective featuring Sobono Group

UOB highlights Sobono’s insights on the concept of circular solutions and how “Inspiring Boldness” holds the key towards creating an extraordinary and sustainable clean and green design. Featured in the article is our FiT-Certification Biogas Co-generation plant. The path towards circularity can be a long and sometimes arduous journey which Sobono is glad to share through this interview.

The formulation of the circular concept was not conceptualised from the beginning, or at least not at the grand scale achieved today. Nevertheless, it was a natural and logical path as we engaged the client and the local communities. The adopter of circular economy model needs to have a BOLD vision to do what is right, protecting and creating a sustainable environment and uplifting the livelihood of the local communities.

The resources on Earth are finite; hence a circular economy mentality enables business owners to achieve maximum resource efficiency, reduce operating costs and secure inclusive upstream supplies and downstream off-take.

Circular and sustainable solutions are iterative and get finetuned given time and constant feedback from upstream and downstream nodes. Therefore, perseverance and adaptability in seeing through your design is one of the key attributes in the success of any circular system design. Find out more by downloading the full Industry Perspective: https://www.uobgroup.com/industry-insights/consumer-goods/harnessing-waste-to-cut-costs.page

SLNG – Sobono Group Awarded JIIC 2021 with RUV Concept

Congratulations to Sobono Group for being awarded the winner of the Jurong Island Innovation Challenge 2021!

Sobono was invited by SLNG to address their challenge of recovering and utilising vessel return gas (RUV). This gas is produced when vessels and barges enter the SLNG facility to offload their LNG cargo and have the gas extracted from their tanks while they wait to load other cargoes.

The team’s waste to energy expertise, experience and collaboration has provided a good foundation for exploring solutions for the RUV.

Through an innovative circular approach, Sobono explored the use of a deep analytics tool (DAT) for the Recovery and Utilisation of Vessel Return Gas (RUV) challenge. Sobono believes that effective energy management is derived from closing the resource loops.

Integrating a digital deep tech solution, Sobono visualised the utilisation values and benefits of vessel return gas.

This was achieved through the analysing of the waste to the energy process and with the assistance of Deep Analytic Tool (DAT), which helped to determine the optimal solution for RUV.

Winning the JIIC 2021 award is only just the beginning as Sobono seeks to build up the RUV with all its complexity and many challenges.

Looking Ahead – Jan 2022

2021 has certainly felt like a long drag, and was somewhat difficult, frustrating and challenging. However, reflecting on the year just over, I also recognized many wonderful achievements for Sobono group of companies:

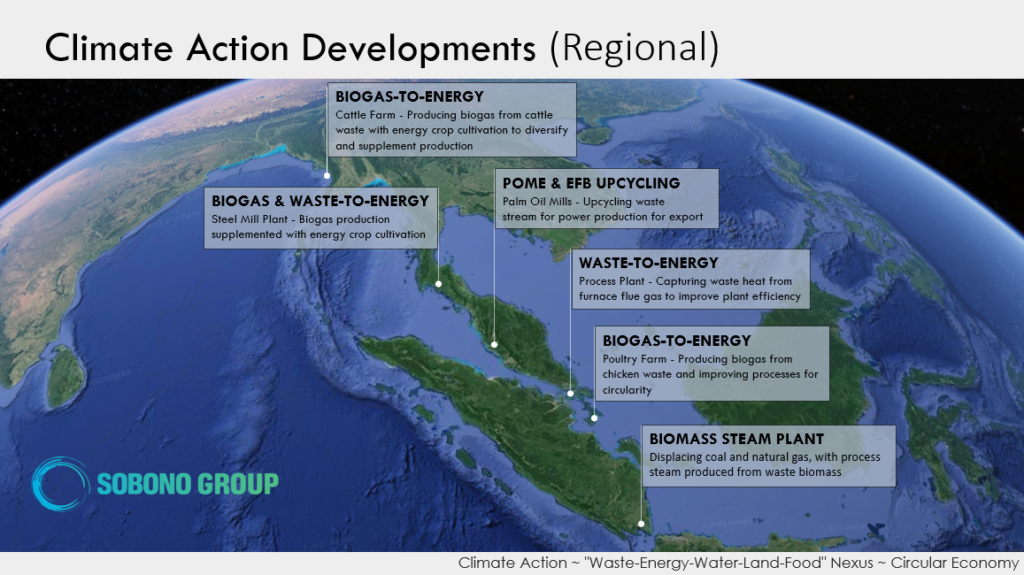

- We developed many new client relationships in Singapore, Indonesia, Malaysia and Thailand; and are grateful for the opportunities these client partners have entrusted in us as they pursue climate actions and work to reduce their carbon footprints.

- With COVID-19 and various safe management measures, the Sobono team was compelled to adjust operations and business models, and have risen to the occasion and demonstrated the resolve and resilience to overcome setbacks, seize new opportunities and become stronger in the process.

- We have also developed better waste-to-energy solutions (including those for green and food wastes) which are more competitive, easy to deploy and provide better financial returns, for offering to our clients.

- More particularly, a new organization structure of Sobono Pte Ltd had been put in place in 2021 to further support our future long-term investments in clean and green energy plants as well as Resilient Nexus Farms.

I am thankful for the ongoing supports of all our stakeholders throughout the year.

Looking ahead to 2022, I look forward to the successful rolling out of activities and initiatives to support our recovery and growth journeys; including the capital raising and green financing for Sobono Pte Ltd; contracting and deliveries of various bold and unique climate action projects by Sobono Energy and Sobono Greenland, centred on the solutions and products that we developed and offered. I believe the successes of these earlier projects could significantly demonstrate the viabilities of circularity and the important linkages within the ‘Waste-Energy-Water-Land-Food’ nexus, and could attract many more adopters in the coming years. While Sobono group of companies taps on and benefits from the green growth opportunities on the environmental sustainability front, I hope to provide inputs and opinions to help shape the sustained growth of the industry; and to engage and support other SMEs and entrepreneurs that have similar mindsets as us.

2022 shall remain a year to “Inspire Boldness”. Wishing all members of Team Sobono and friends a very Happy New Year!

Wee Khoon OH

Managing Director / Executive Director

Sobono Group of Companies

1 January 2022

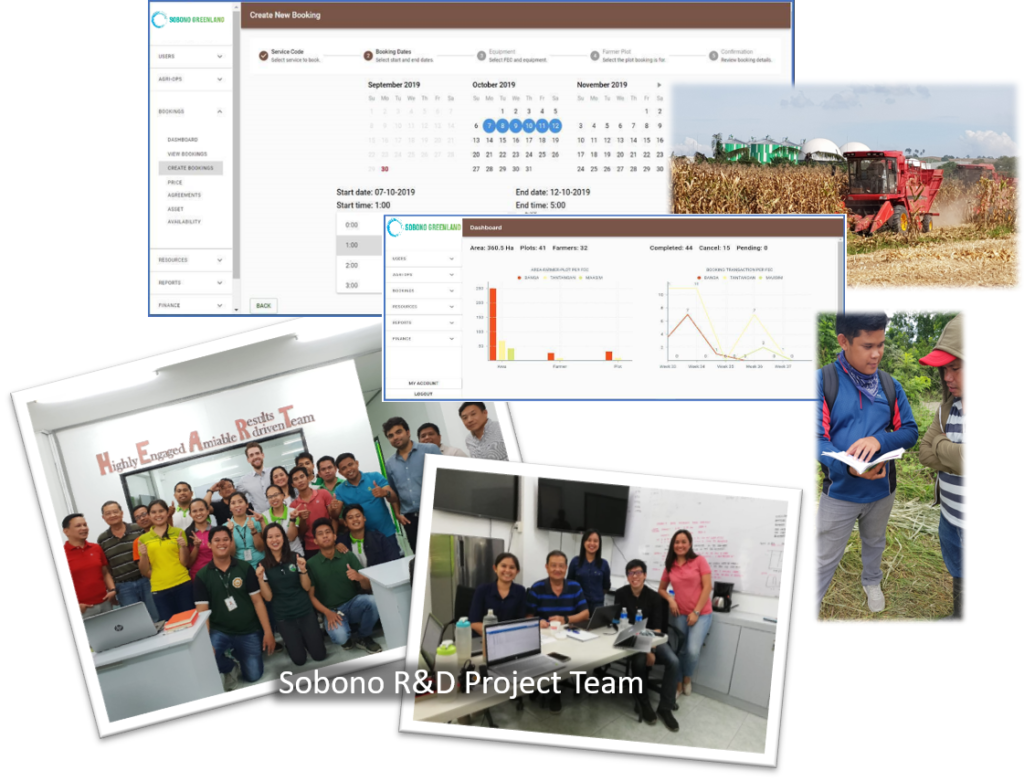

Agriculture Operations – ANI & Farm Equipment Booking Module Development

Sobono Greenland commenced the use of Farm Operations and Logistics Management System Feedstock Security (ANI, which means ‘harvest’ in Tagalog). ANI is an in-house developed software that manages Agribusiness, equipment deployment, material control and farming protocols for large-scale farming. ANI also serves as a plug-in for Xero, a financial software program, to streamline accounting and purchase functions.

This Sobono Greenland’s farm planning App was brought about in 2 phases.

Phase 1 involves a ‘Booking Module’ Joint Development while Phase 2 involves the development of ANI.

- Farm Operations and Logistics Management System Feedstock security (ANI); “Harvest” in Tagalog), in-house developed software that manages Agribusiness, equipment deployment, material control and farming protocols for large-scale farming. ANI also serves as a plug-in to a financial software program (e.g., Xero) to streamline accounting and purchase functions

- A Farm Operations and Logistics Management System (ANI); “Harvest” in Tagalog):

- ANI manages large-scale agribusinesses, land lease & sales contracts, equipment deployment, material control and farming protocols

- ANI also plug-in seamlessly to a financial software program (e.g., Xero) to streamline accounting and purchase functions

Farm Planner

- pending patent application. In two-phase product development, each phase to develop a fully functional system, the final ANI system provides the full system complexity

- Phase 1 “Booking Module” Joint Development (in SG & PHP) –(system in operation), completed in Aug 2019

- Phase 2 “ANI” Development (in SG) to be completed in Mar 2021

Awarded ECPM project for 12.5 MWE FiT-Certification of Biogas Co-Generation Plant Expansion

Sobono Energy has been awarded an EPCM expansion project to increase production to 12.5MWE, up from the existing 9.7MWE after the previous expansion. This expansion supports Biotech Farms Inc. as they ramp up their food production to meet increasing food demand. The team will continue to engineer systems that are robust and capable of handling waste.

“The synergistic effect between increase food production gave rise to higher energy production. Making it a win-win solution.”

Additional 2.8MWE electricity generated from the biogas displaces ~0.2 kg CO2/kWhE, this sums up to 4,905.6 TCO2 reductions annually.

Introducing High-Performance Heavy Machinery to Largescale Agriculture

Heavy construction equipment is not just for urban civil works. In developing and maintaining largescale farmland, such heavy equipment becomes a necessity where speed, capacity, versatility and reliability are important attributes.

Sobono Greenland is proud to introduce CASE backhoes and wheel loaders to the fleet of workhorses in our agricultural land development.

Product operation and maintenance training is an essential part of Sobono Greenland’s protocol to ensure the safety of our operators and improved productivity with reduced breakdown and turnaround time for our equipment.

Sobono Greenland Commissions its First Fleet of Farm Tractors and Implements

Sobono Greenland proudly announced the arrival of our first agricultural tractors and farming implements in South Mindanao.

These farm workhorses range from 50 to 115 hp coupled with farm implements such as harrowers, maize choppers, pneumatic seed planters, laser levelers, manure spreaders, dump trailers, etc.

These new additions provide much of the farmland cultivation needs and inject a much-needed modernization in the region. As the cultivation area increases, larger and much more powerful tractors with high-capacity implements will be introduced in phases.

Corn Cultivation in South Mindanao – Corn Pickers in Action

Sobono Greenland proudly put its first corn pickers into operation in the cornfields of South Mindanao.

Such mechanization provided much-needed productivity in the field where manual harvesting of corn cob is still in practice today in the southern Philippines. A small corn picker is capable of harvesting a hectare within an hour.

The stovers (left behind corn stalk) are shredded and the organic matter is returned to the soil as harvest in one single harvesting process.

Traditionally, farmers would rely on burning the stover to prepare the land for the next crop.

This effort lends a hand to improving circularity and greatly reducing the slash and burn events.

Asian Power & Energy Innovation Award at PowerGen Asia 2019

Recognised for their sustainable waste-to-energy effort, N&N Agriculture Pte. Ltd., was presented the Asian Power & Energy Innovation Award through the implementation of the Capstone Microturbine system, a project managed by Sobono Energy Pte. Ltd.

The co-generation system of thermal and power is fueled by biomethane which is derived from the anaerobic digestion of chicken manure.

The backend waste stream provided the organic ingredient for the regeneration of topsoil.

This award celebrates both innovations in energy and circularity.

Receiving the award is Mr Ma Chin Chew, Director of N&N Agriculture (centre) and in accompany, Mr Jason Teoh, General Manager of Sobono Energy (left).

Receiving the award is Mr Ma Chin Chew, Director of N&N Agriculture (centre) and in accompany, Mr Jason Teoh, General Manager of Sobono Energy (left).

Introduction of Napier as Energy Crops – Biogas Cogeneration Plant Expansion

Napier grass was introduced as a consistent feedstock to supplement Biogas-to-Power Plant expansion at Biotech Farm Inc. Leading this new initiative is Sobono Greenland which partners Sobono Energy in providing suitable and reliable feedstock supply for power production.

Napier grass was a perennial tropical crop used as fodder. The tender young leaves and stems are very palatable for livestock. Napier grass grows fast and is propagated easily. In recent years, Napier grass started gaining traction to be used as an energy crop. It is reported that 1 ton of Napier grass can produce 90m3 of biogas and the heating value for compressed biogas produced from its biomass is 14-18MJ/kg.

Napier grass was a perennial tropical crop used as fodder. The tender young leaves and stems are very palatable for livestock. Napier grass grows fast and is propagated easily. In recent years, Napier grass started gaining traction to be used as an energy crop. It is reported that 1 ton of Napier grass can produce 90m3 of biogas and the heating value for compressed biogas produced from its biomass is 14-18MJ/kg.

“We had conducted field studies to identify the appropriate species that thrive in the given environment. The outcome of the feedstock studies provides reliable and sustainable supply for energy production.” – Operations Executive, Mr Chester Tan

Introducing Napier grass to the biogas system changes the substrate characteristics, hence proper assessment and upgrading are required to ensure smooth conveyance and complete anaerobic digestion. To this end, Sobono Group shall lead the plant expansion and optimization projects aimed at incorporating Napier grass into the system to increase energy production.

Incorporation of Sobono Greenland Pte. Ltd.

Sobono Greenland became part of Sobono Group family on the 1st of Oct 2018!

We like to welcome the birth of this new partnership.

Sobono Greenland Pte. Ltd. was formed with the intention to focus on agri-tech development, biomass feedstock management, large-scale farming, agriculture waste upcycling and sales of agriculture equipment; with a purposeful drive towards circularity and sustainability.

We wish Sobono Greenland Pte. Ltd. wholeheartedly an amazing journey ahead!

Biogas Power Plant with WWTP EPC – Oct 2017

Sobono Energy was awarded, together with Alensys Engineering GmbH, a contract by Biotech Farms Inc in Banga, Philippines to design a Biogas Power Plant (BPP) with a Wastewater Treatment Plant (WWTP), providing engineering, procurement, project management services for the project. The Plant is designed to manage animal wastes from the poultry and pig farm, producing up to 2.8MW of electrical power, treating the discharges to meet the Department of Environment and Natural Resources (DENR) effluent standards. Start-up and commissioning is targeted for Q4 2017.

Operation & Maintenance Contract – May 2017

Alensi Philippines Corp., subsidiary company of Sobono Energy was awarded, an Operations and Maintenance (O&M) contract by Biotech Farms Inc to provide O&M services for the 2.8MW Biogas Power Plant in Banga, South Cotabato and the 5.5MW Biomass Power Plant in Tantangan, South Cotabato.

Biomass ORC Plant EPC – May 2017

Sobono Energy was awarded a contract by Biotech Farms Inc in Tantangan, Philippines to act as the integrator for a Renewable Energy Biomass to ORC Power and Hot Water Co-generation Project, providing engineering, procurement, project management support. The Plant is designed to operate under 2 modes – ‘CHP’ Mode or ‘Power-only’ Mode. In the Power-only Mode, the ORC produces gross power output of 5,500 KWe. Start-up and commissioning is targeted for Q4 2017.Sobono Energy was awarded a contract by Biotech Farms Inc in Tantangan, Philippines to act as the integrator for a Renewable Energy Biomass to ORC Power and Hot Water Co-generation Project, providing engineering, procurement, project management support. The Plant is designed to operate under 2 modes – ‘CHP’ Mode or ‘Power-only’ Mode. In the Power-only Mode, the ORC produces gross power output of 5,500 KWe. Start-up and commissioning is targeted for Q4 2017.

Microturbine C65 – May 2014

Sobono Energy was awarded a contract by National University of Singapore (NUS) in Singapore to provide a unit of C65 with Integrated Hot Water Economizer (HWE) for R&D applications. The C65 will be operated with Compressed Natural Gas (CNG). Start-up and commissioning is targeted for Q3 2014.