Energy Solutions

Energy Solutions

Biogas

As we are all aware, the push for increased renewable energy sources has gained momentum for the past few years. While the use of traditional methods to generate energy is still prevalent, Biogas has been one of the alternatives to create an environmentally-friendly energy source because of its ability to alleviate two major environmental problems simultaneously, such as:

- The global waste epidemic that contributes to high levels of methane gas production every day.

- The reliance on fossil fuel energy to meet global energy demand

Do you want to know how?

Biogas is produced after organic materials (plant and animal products) are broken down in an Anaerobic Environment (an environment absent of oxygen) to release a blend of gases, primarily methane and carbon dioxide. Due to the high concentration of methane within biogas (typically 50-65%), it is energy rich and can be used as an fuel source, being combusted in the Capstone MicroTurbine® or Biogas engines to produce electrical power and thermal energy.

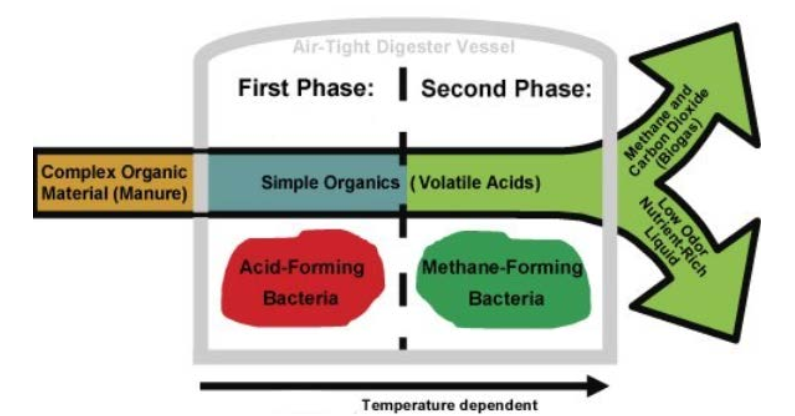

Anaerobic Digestion Process

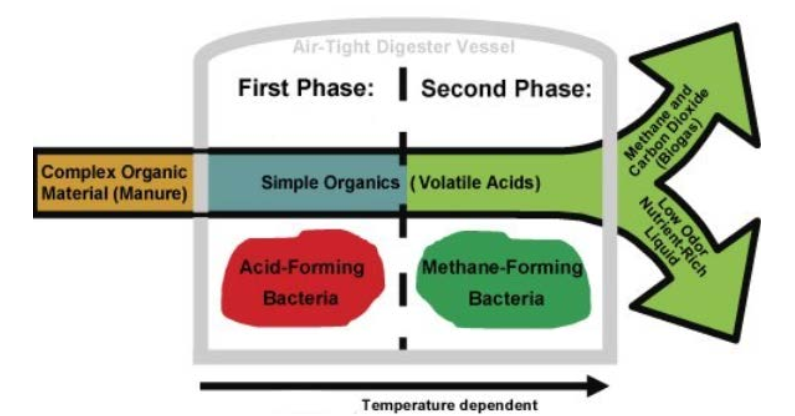

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels

- Without oxygen, naturally occurring anaerobic bacteria thrives.

- These bacteria carry out the anaerobic digestion process without the need for

additional enzymes. - In a continuous process, the process breaks down organic substances into volatile acids before producing Biogas and stable digestates, thereby also reducing pollution loads from industrial or farming processes.

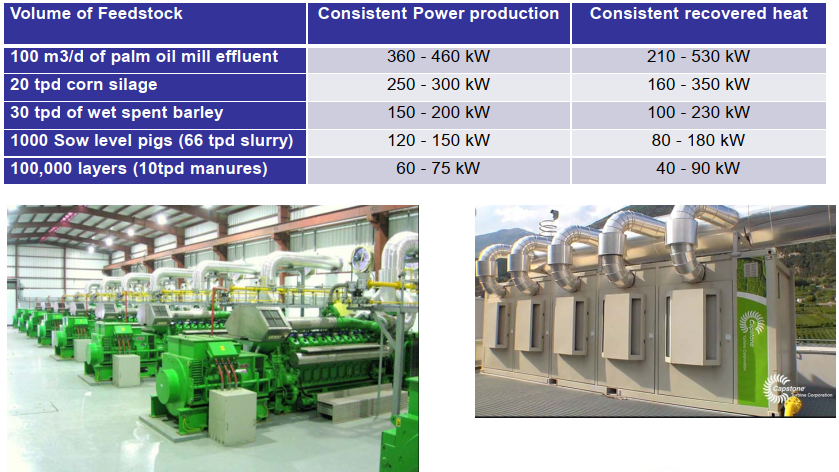

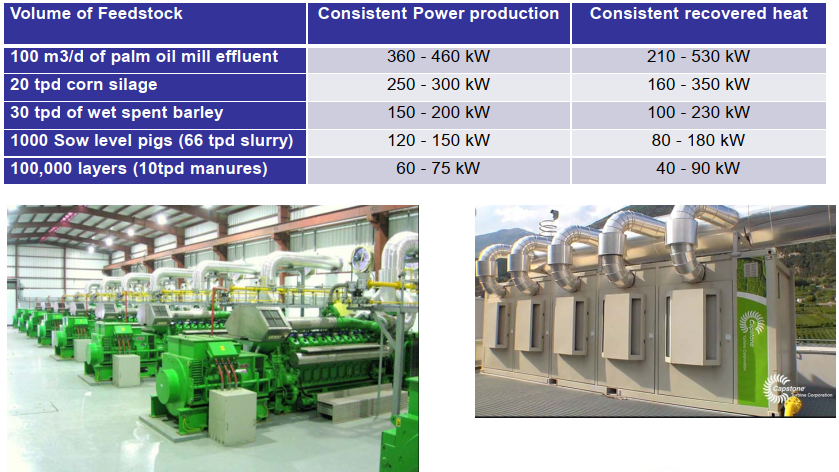

Input (Feedstock) and Output

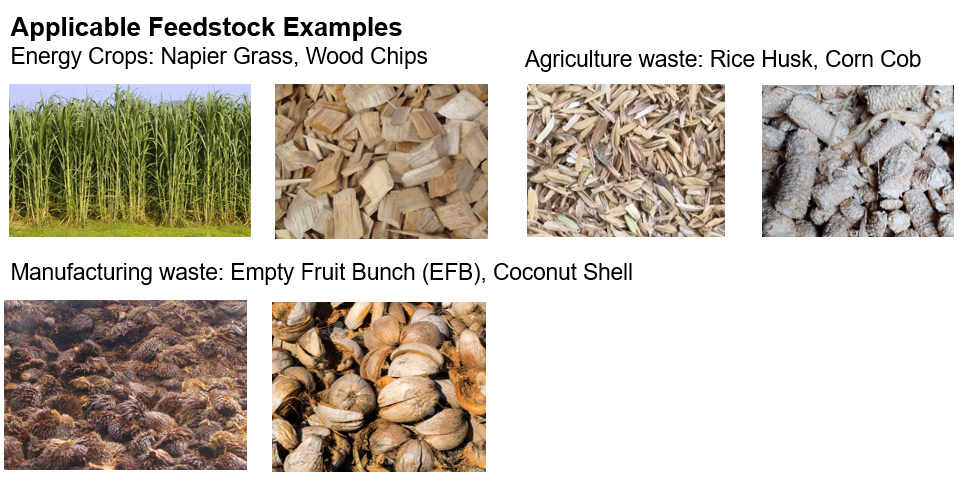

Most types of organic wastes can be added to the high functioning biogas plant as feedstock, ranging from energy crops, agricultural waste, fruit waste and manufacturing wastes

Biogas produced can be burnt in Combined Heat and Power (CHP) systems

to generate power and heat

Biomass

There are several types of biomass processing technologies currently available. Sobono Energy focuses on anaerobic digestion (biogas solution highlighted above) and direct combustion of biomass (for electrical and thermal power), two of the more mature and proven methods.

Plants absorb the sun’s energy through the process of photosynthesis. When biomass is burned, the chemical energy in biomass is released as heat in the form of flue gas. The thermal energy from the flue gas is used to drive the Organic Rankine Cycle (ORC), to produce electrical power and thermal power. This highly efficient process maximizes the energy input of the raw biomass into useful energy forms of electricity and heat.

There are many types of waste material that can be classes as biomass to be used in a biomass furnace as fuel. Common types include rice husk, corn cobs, shredded Empty Fruit Bunch (EFB). Diverting these waste materials to a biomass power plant for power production fully utilizes our resources instead of them becoming problematic waste byproducts, costing time and effort to dispose of.

Input (Feedstock) and Output

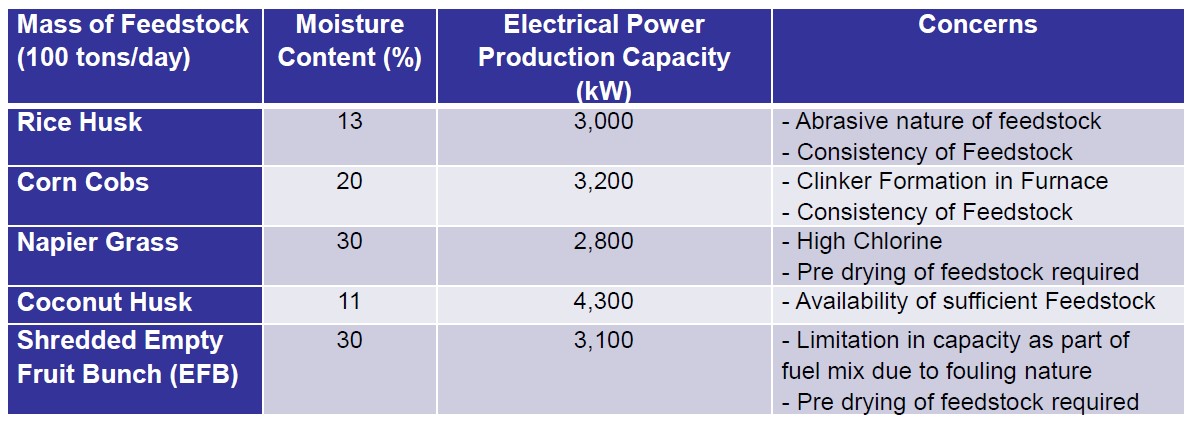

Each fuel type has its own characteristics, energy value and unique requirements in the design of the biomass furnace. To maintain a highly efficient furnace and overall process, it is desirable for the fuel to be fed into the furnace at a moisture content of 30% or less.

The below table represents the Power productions generated based on the mass of Feedstock (100tons/day).

Organic Rankine Cycle (ORC)

The ORC is highly robust and reliable process based off the Rankine Cycle, which is a thermodynamic cycle that converts heat into work. In the Rankine Cycle, heat is supplied to a closed loop, which typically uses water as working fluid. The typical application of the Rankine Cycle based on water are steam turbines which generate the majority of worldwide electricity production.

The Organic Rankine Cycle’s principle is based on a turbo generator working similarly to the conventional steam turbine. Thermal energy captured from the Biomass furnace is transformed into mechanical energy and finally into electric energy through an electrical generator. Instead of generating steam from water, the ORC system vaporizes an organic fluid, which is characterized by a higher molecular mass than water, which allows a slower rotation of the turbine, significantly lower operating pressures and no erosion of the metal parts and blades.

Capstone Microturbine®

Sobono Energy is the Authorized Distributor of Microturbine® Generator Systems of Capstone Turbine Corp.

Capstone Microturbines are able to cleanly and effectively run on methane gas produced from landfills, wastewater treatment facilities and food processing facilities, as well as agriculture waste, which is often referred to as “green waste.

With a Global Warming Potential (GWP) of 21, or 21 times that of carbon dioxide, it is critical that for methane gas produced from these processes and facilities to be captured. Rather than simply venting or flaring the methane gas, Capstone Microturbines can convert this fuel to clean and reliable electricity for use at the site or surrounding areas.

Input (Feedstock) and Output

Offering multiple sizes from the compact 30kW unit to the industrial scale 1000kW, the Capstone Microturbine has different solutions catered for the varying fuel types, including Natural Gas, Liquid Fuels, Biogas, Sour Gas and LPG (including high butane LPG).

View the full list of Capstone products here

Through advanced engineering, extensive R&D and holding more than 100 patents, the Capstone Microturbines is in a class of its own. By integrating an aero-based turbine engine, a magnetic generator, advanced power electronics, with patented air bearing technology, Capstone Microturbines are the ideal solution for today’s distributed energy needs.

Learn more about the technology behind the Capstone Microturbine here

Waste Heat Recovery

In many industries, excess heat is usually generated during the operations that is wasted and dumped into the environment. Through implementation of Sobono Energy’s Waste Heat Recovery Solutions, waste heat can be utilized to provide valuable energy sources which can ultimately be used to increase the efficiency in the recovery process, significantly decrease the costs of fuel and energy consumption required for operations.

Below are the benefits of using the waste heat recovery technologies.

Indirect benefits

1. Reduced Pollution: Thermal and air pollution will dramatically decrease since lower quantities of flue gases at high temperature are emitted from the plant with large proportions of the energy being recycled.

2. Improved company profile: With increased emphases on energy efficiency and utilization, the overall profile of the company improves as a sustainable and forward thinking company. This makes the company more attractive to potential investors and to attract global talent.

Operations and Maintenance (O&M)

Operations and Maintenance is a complementary service offered to our customers. We upkeep the equipment and installations to an extremely high standard. Going beyond the basic operational procedures of inspecting, cleaning, servicing, preserving and lubricating, the team also develops the robust preventive maintenance program unique for each plant, including recording of operational parameters and investigating the long-term trends to ensure that our O&M team preempts problems before it even arises.

Through a combination of technical knowledge, organizational skills, and management skills, our O&M team run the operations and maintenance of each plant effectively and efficiently. We believe that having a strong team is part of our success to help our clients, achieving their long term goals, with a safe, reliable and high functioning plant.

Energy Solutions

Biogas

As we know, renewable energy sources has gained their momentum for the past few years. While many are still using the traditional way to generate energy, Biogas has been one of the alternatives to create an environmentally-friendly energy among businesses because its ability to alleviates two major environmental problems simultaneously, such as:

1. The global waste epidemic that releases dangerous levels of methane gas every day.

2. The reliance on fossil fuel energy to meet global energy demand

Do you want to know how?

Biogas is produced after organic materials (plant and animal products) which will be broken down in an Anaerobic Environment (an environment absent of oxygen) to release a blend of gases, primarily methane and carbon dioxide. Due to high concentration of methane within biogas (typically 50-65%), it is energy rich and can be used as an energy source, being combusted in the Capstone MicroTurbine® or Biogas engines to produce electrical power and thermal energy.

Anaerobic Digestion Process

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels

- Without oxygen, naturally occurring anaerobic bacteria thrives.

- These bacteria carry out the anaerobic digestion process without need for

additional enzymes. - In a continuous process, the process breaks down organic substances into

produce Biogas and stable digestates, thereby also reducing pollution loads.

Input (Feedstock) and Output

Most types of organic wastes can be added to the high functioning biogas plant as feedstock, ranging from energy crops, agricultural waste, fruit waste and manufacturing wastes

Biogas produced can be burnt in Combined Heat and Power (CHP) systems

to generate power and heat

Biomass

Biomass is a process to generate heat energy and other forms of energy depending on the process of the decomposition of various type of waste such as, wood waste, agricultural waste, municipal solid waste, manufacturing waste, and landfill gas. It also includes plant or animal matter that can be converted into fuel, fibers or industrial chemicals. Diverting these resources to produce energy is essential, otherwise, it will be a problematic waste streams.

Output

While Biogas is mainly composed of methane and carbon dioxide, Biomass is composed of biological material. It helps generate various of energy based on the where the sources are derived from. For instance, using sugarcane and corn starch, it generates fuel cell to produce electricity.

Capstone Microturbine®

With the use of an anaerobic digester, Capstone microturbines are able to cleanly and effectively run on methane gas from landfills, wastewater treatment facilities and food processing facilities, as well as agriculture waste, which is often referred to as “green waste.” Rather than simply venting or flaring the methane gas, Capstone microturbines can convert this free fuel to clean and reliable electricity for use at the site or surrounding areas. Capstone offers its “CR” (Capstone Renewable) line of microturbines specifically designed to operate on waste gas fuels.

Waste Heat Recovery

Industrial waste heat is the energy that is generated in industrial processes which is not put into any practical use and is lost, wasted and dumped into the environment. Recovering the waste heat can be conducted through various waste heat recovery technologies to provide valuable energy sources and reduce the overall energy consumption.

The recovery process will add to the efficiency of the process and thus decrease the costs of fuel and energy consumption needed for that process.

Indirect benefits

1. Reduced Pollution: Thermal and air pollution will dramatically decrease since less flue gases of high temperature are emitted from the plant since most of the energy is recycled.

2. Reduced equipment sizes: As Fuel consumption reduces so the control and security equipment for handling the fuel decreases. Also, filtering equipment for the gas is no longer needed in large sizes.

3. Reduced auxiliary energy consumption: Reduction in equipment sizes means another reduction in the energy fed to those systems like pumps, filters, fans,etc

Operations and Maintenance (O&M)

Operational and Maintenance Service is what we provide to our customers. We help them to maintain the quality of the in-field and off-field equipment to ensure the efficiency of the production is always at the top level. This category of operational maintenance normally consists of inspecting, cleaning, servicing, preserving, lubricating, and adjusting, as well as inspecting the machine to spot any changes or issues. This allows the operator to detect a potential danger, such as loose fasteners or debris that could contribute to an accident. Basic cleaning, including removing debris or excess grease from a machine, is also considered part of operational maintenance.

Our team has a combination of technical knowledge, organizational skills, and management skills which they use to run their operational effectively. We believe that having a strong team is part of our success to help our clients.